Certified quality and trailblazing production

ARI®’s comprehensive quality management system and state-of-the-art methods ensure the reliability, durability and safety of all our products. This includes continuous quality monitoring according to DIN EN ISO 9001 at all stages of production as well as additional quality management certifications – for example, in line with ASME, SELO, IBR, DNV, BV, LR, RINA and NK.

Leader in innovation

The high quality of ARI® products starts at the development stage. Three development teams are involved in implementing new ARI® product ideas – complemented by a trial team to validate theoretical data and five design groups for product updates and custom design.

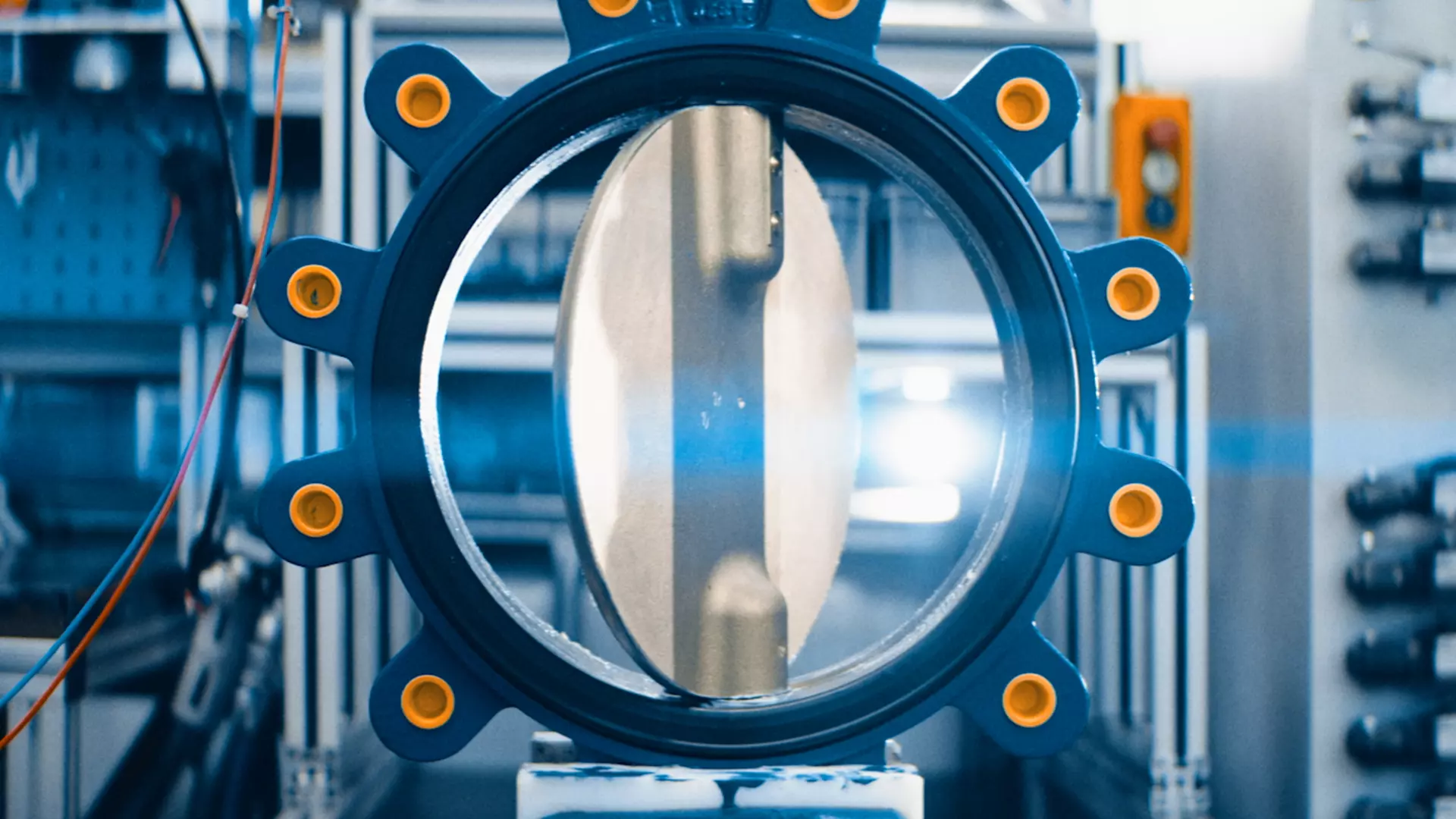

Using finite elements, flow simulations, firesafe tests, characteristic curves and contact angle calculations, we are continually working using the latest development methods. ARI® also uses sophisticated software for development, calculation and virtual product simulation (CFD + FEM). A 3D printer is available for rapid prototyping in-house to validate designs.

Prototypes are tested under the most demanding conditions in our own test facilities. This also involves numerous test fields – for example for steam, water, air, heat transfer oil and cryogenic applications.

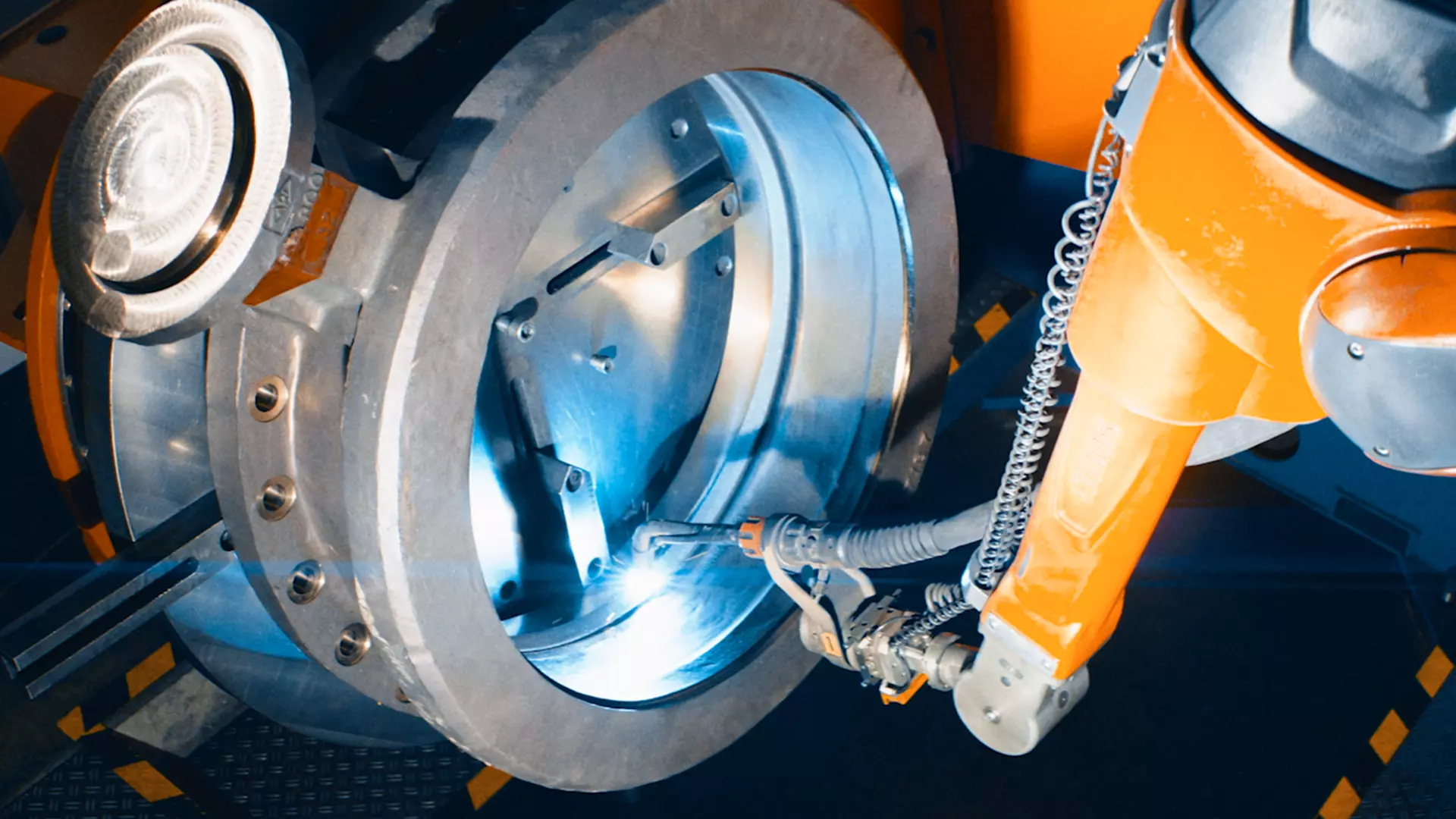

State-of-the-art production

The manufacture of industrial valves at our three production sites in Germany is also designed with maximum precision – ensured by our standardised ARI® production system (APS). With product-oriented manufacturing in production systems, integrated digital processes, continuous investment in the latest manufacturing technology and a high degree of automation, ARI® guarantees maximum reliability, durability and safety. Every part of every valve is tested down to the finest detail.

You may also be interested in

Here you will find related topics and further information about ARI-Armaturen.